Products

The V3C models are the most mature machines with the widest application range. They are also the most reliable and

automated machines. Features:

- One piece design for the injection system The most efficient oil circuit with excellent injection performance.

- Integrated structural rigidity with self-lubrication design for long service time.

- Easy to install peripheral equipment for automation, which increases efficiency and saves man power.

- User-friendly Man-Machine Interface (MMI) with alarm device.

- Multi-stop injection adjustment provides a reduction of swelling gas in the barrel, while upgrading die casting product quality.

- There are three injection models including soft start with constant speed injection, constant acceleration injection and multi-stage injection for flexible production.

- The use of a P/F valve helps to increase convenience of operation while reducing electricity consumption up to over 15%.

- Available to be equipped with a servo controlled energy-saving electrical system for saving electricity consumption up to 50%.

- The Full Test function provides a simulation of die casting process that allows the operator to realize the aluminum liquid flow condition during a molding cycle.

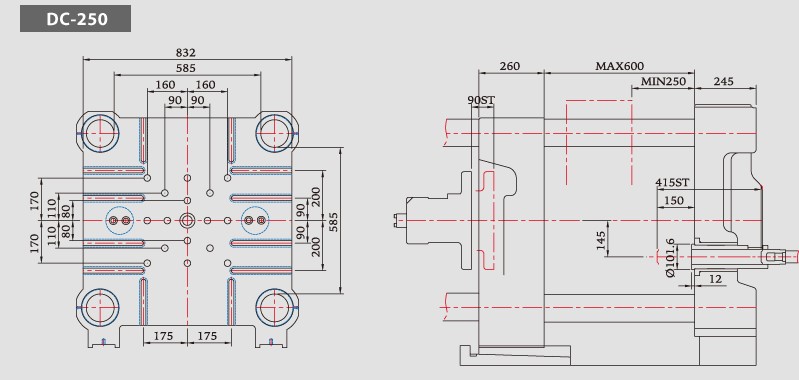

| Clamping force | 250 Ton |

| Die height | 250-600 mm |

| Tie bar distance | 585 x 585 mm |

| Max. weight of shot | 2.75 kg |

| Max. casting area | 714 cm² |

| Electricity | 22.5 kw |