Products

Product Information

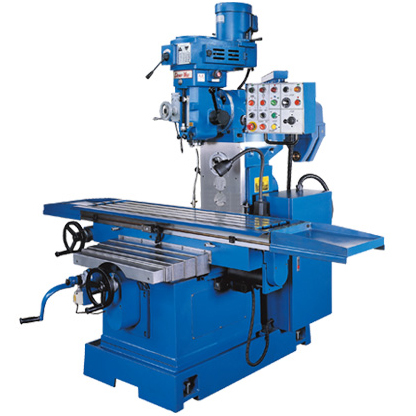

•All casting is finished through annealing stress with M casting iron; the slides for X, Y, Z, axle are handled by heating and grinding; the sliding for X, Y, axle is light and clever without abrasion because of pasting anti-abrasion pieces. We use C5 level for X, Y, axle, pre-pressed nut of precise bead-rolling rod, which is to press smoothly and position well due to small gap. Using the timing oil-filling on X, Y, Z axle and nut to ensure the precision for each section.

•A fixed working table, a contact plane between the width of the saddle and the working table is so long that allows a high stability of processing.

•A wider table plane is able to emphasize a rigidity and tenacity.

•Using server auto-feeding on X.Y axle for over 2500 series and reducing working hours by rapid up and down motions. In order to reach a rapid up and down motion, Z axle is a function of reducing speed.

•Using a cannon head with strong structure of vertical milling head. The inside grinding gear is to fill oil by enforcement, 20-stage transmission. (it’s optional to select frequency non-stage transmission.) To shorten the working time and upgrade the enterprise competition because the core of the axle is able to have a boring automatically.

|

MODEL |

2500SVH |

|

TABLE |

|

|

Working surface of table |

1500x352mm |

|

Longitudinal travel |

1050mm |

|

Cross travel |

350mm |

|

Vertical travel |

390mm |

|

T-slots (size x number x distance) |

18mx3x70mm |

|

Range of longitudinal feeds (mm/min) |

0-1200mm/min |

|

Rapid longitudinal traverse (mm/min) |

2300mm/min |

|

Rapid vertical traverse |

500mm/min |

|

HORIZONTAL SPINDLE |

|

|

Range of spindle speeds (6set teps) |

60Hz: 86-915 R.P.M 50Hz: 72-763 R.P.M |

|

Taper of spindle nose |

NST40 |

|

Distance of spindle center to table |

100mm-490mm |

|

Distance from spindle center to overarm |

190mm |

|

VERTICAL SPINDLE |

|

|

Range of spindle speeds (20set teps) |

60Hz: 50Hz: |

|

Spindle travel |

140mm |

|

Taper of spindle nose |

NST40 |

|

Swivelling angle of vertical milling head (R&L) each side |

90° |

|

Distance of spindle end to table top |

Max 615 / Min 220 |

|

Swivelling overarm |

360° |

|

Traverse of over arm |

450mm |

|

Feed of spindle (3 steps) |

0.035 / 0.07 / 0.14 mm(PER REV.) |

|

Distance of spindle center to column surface |

110mm-700mm |

|

MOTORS |

|

|

Vertical spindle |

5HP2/4P |

|

Horizontal spindle |

7.5HP4P |

|

Table longitudinal feed |

DC (Server Motor) |

|

Column up-down |

1HP (Redicing Motor) |

|

Coolant pump |

1/8HP |

|

Net weight |

2200-2500Kg |

|

Packing Measurement (Seaworthy wooden case) |

1690x1790x1810mm |

|

※ There will be some changes for the specification and the design from time to time without any prior notice. |

|

|

STANDARD ACCESSORIES:

OPTIONAL ACCESSORIES:

|

|