20YRS

CHIAN CHANG MACHINE CO., LTD.

Products

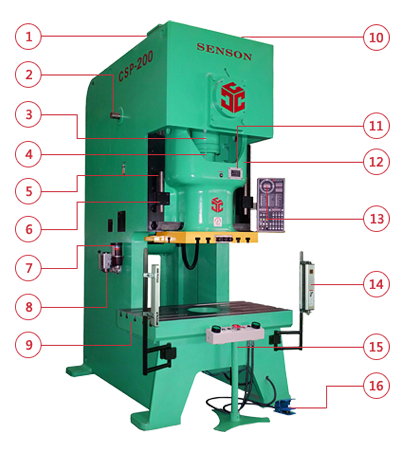

C-Frame Single Crank Precision Power Press

C-Frame Single Crank Precision Power Press

CSP 系列

25 ~260 tons

Broad slide bottom and bolster are suitable for drawing and punching operation with various automotive, motorcycle and machine components, appliance and hardware parts, and computer parts like Cases, CD-ROM, Fans, and PC boards.

Specification

- Counter balancer (Equilibrating cylinders)

- Power take-off feed shaft (feed direction: left→right)

- Connecting rod

- Ball Rod

- Six-face wide-and-long guide rail

- Knock out device

- Manual grease pump

- Oil pump

- Bolster

- Anti-repeat device (Overrun detector)

- Die Height Indicator

- Slide

- Crank angle LED display

- Safety light curtain

- Portable push button operation stand

- Foot switch

- Encoder

- Touch screen control panel and box

- Air pressure regulator

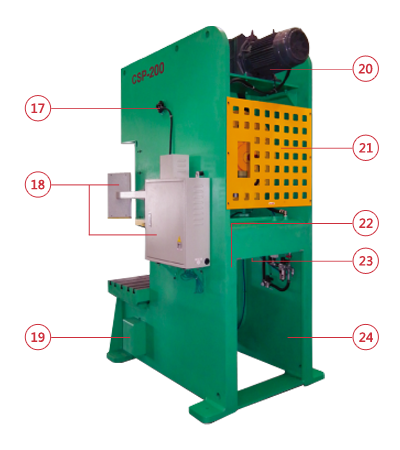

- Main motor [Variable speed(V.S) motor for overseas market]

- Wet Type Clutch Brake

- Slide adjust motor

- Hydraulic overload protector

- High rigid frame

Standard Accessories

| Operation modes ("off", "inching"/"single"/ "safe single"/"continuous") | Wet type clutch brake | Counter balancer (Equilibrating cylinders) |

| Motorized slide adjuster | Die height indicator In 0.01mm increments for CSP-25 ~ 60, In 0.01mm increments for CSP-25 ~ 60, In 0.1mm increments for CSP-80 ~ 260. |

Encoder |

| 360°Crank angle LED display | S.P.M. LED display | Product lot counter (Preset, 6-digit) |

| Total counter (Preset, 6-digit) | Brake angle monitor device | Cutting outlet: 2-set |

| Spare electronic rotary cams: 4-set | Mileage maintenance reminder | Pre-date/month/year production performance recorder |

| Inverter (or Variable speed V.S. motor -for overseas market) | "FOR." & "REV." modes for main motor | Knock out device |

| Manual grease pump | Air ejector | Air source socket |

| Power socket 220V, 5A (for overseas market) | Power take-off feed shaft (feed direction:left→right ) | Portable push button operation stand |

| Rubber mount (shock absorber) | Maintenance tools with box | Operation Manual |

| Safety devices for protecting workers or tools | |||

|---|---|---|---|

| Hydraulic overload protector | Mis-feed detective circuit: 3-set (A,B) | Anti-repeat device (overrun detector) | Safety light curtain |

Optional Accessories

| Pneumatic die cushion | Hydraulic die cushion | Auto grease pump |

| Air feeder | Roll feeder | Auto material straighter |

| PC Board punching removal system | Quick die change system: die lifter, die arm, etc. | Foot switch |

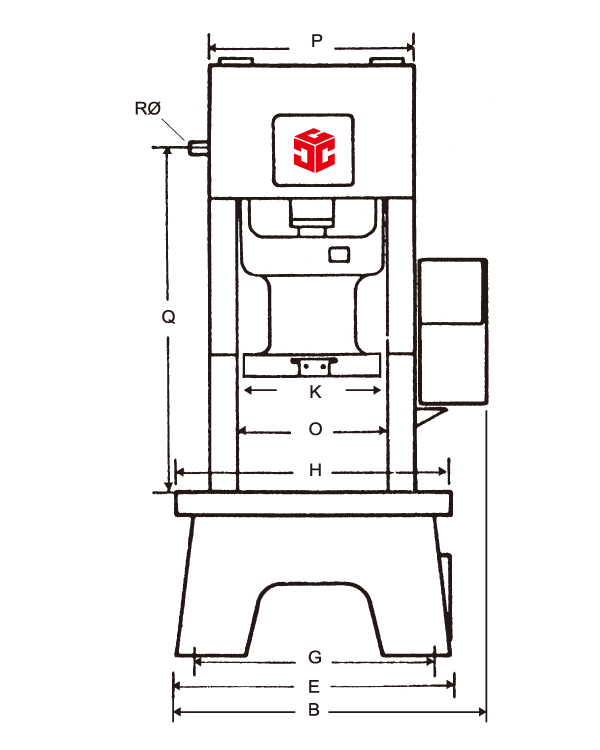

| Model | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q | R |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CSP-25 | 2015 | 935 | 1120 | 1060 | 720 | 900 | 640 | 720 | 340 | 175 | 350 | 260 | 755 | 240 | 400 | 540 | 960 | Ø30 |

| CSP-35 | 2130 | 1015 | 1210 | 1120 | 820 | 950 | 720 | 800 | 400 | 210 | 400 | 300 | 780 | 250 | 480 | 620 | 1050 | Ø45 |

| CSP-45 | 2320 | 1075 | 1320 | 1250 | 900 | 1060 | 800 | 850 | 450 | 230 | 460 | 350 | 780 | 270 | 524 | 680 | 1175 | Ø45 |

| CSP-60 | 2495 | 1140 | 1435 | 1350 | 1000 | 1140 | 890 | 880 | 560 | 290 | 490 | 400 | 810 | 300 | 560 | 745 | 1305 | Ø50 |

| CSP-80 | 2760 | 1235 | 1650 | 1560 | 1100 | 1360 | 970 | 1060 | 620 | 315 | 580 | 460 | 820 | 330 | 600 | 840 | 1470 | Ø50 |

| CSP-110 | 2985 | 1345 | 1820 | 1720 | 1250 | 1470 | 1100 | 1150 | 660 | 340 | 660 | 520 | 860 | 340 | 680 | 950 | 1590 | Ø60 |

| CSP-160 | 3295 | 1480 | 2090 | 1990 | 1480 | 1710 | 1260 | 1350 | 760 | 385 | 720 | 580 | 860 | 400 | 750 | 1070 | 1820 | Ø60 |

| CSP-200 | 3580 | 1680 | 2270 | 2140 | 1680 | 1740 | 1480 | 1500 | 830 | 420 | 860 | 660 | 900 | 450 | 900 | 1250 | 2070 | Ø75 |

| CSP-260 | 3800 | 1780 | 2450 | 2420 | 1780 | 2100 | 1580 | 1600 | 900 | 450 | 960 | 760 | 920 | 470 | 980 | 1360 | 2600 | Ø90 |

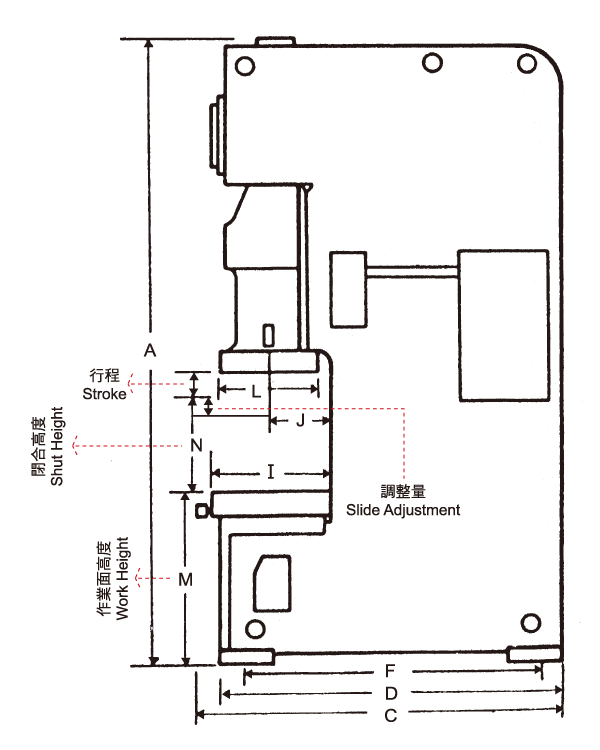

T-Slot Diagram

| Model | A | B | C | D | E | F1 x F2 | G | H1 x H2 | I | J | K | L | M | N |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CSP-25 | 720 | 340 | 130 | - | Ø120 | 260 x 130 | Ø25 | 60 x 60 | 210 | 4 - Ø20 | - | 280 | 350 | 260 |

| CSP-35 | 800 | 400 | 130 | - | Ø120 | 280 x 140 | Ø25 | 60 x 60 | 210 | 4 - Ø20 | - | 320 | 400 | 300 |

| CSP-45 | 850 | 450 | 160 | - | Ø130 | 300 x 150 | Ø25 | 60 x 60 | 210 | 4 - Ø22 | - | 340 | 460 | 350 |

| CSP-60 | 880 | 560 | 200 | - | Ø150 | 320 x 160 | Ø25 | 70 x 70 | 300 | 4 - Ø22 | - | 400 | 490 | 400 |

| CSP-80 | 1060 | 620 | 210 | - | Ø160 | 360 x 180 | Ø32 | 80 x 80 | 280 | 4 - Ø22 | - | 460 | 580 | 460 |

| CSP-110 | 1150 | 660 | 220 | - | Ø200 | 400 x 200 | Ø32 | 90 x 90 | 280 | 4 - Ø25 | - | 560 | 660 | 520 |

| CSP-160 | 1350 | 760 | 290 | 165 | Ø300 | 440 x 220 | Ø32 | 100 x 100 | 300 | 4 - Ø25 | 500 | 660 | 720 | 580 |

| CSP-200 | 1500 | 830 | 330 | 170 | Ø300 | 480 x 240 | Ø32 | 100 x 100 | 360 | 4 - Ø25 | 560 | 760 | 860 | 660 |

| CSP-260 | 1600 | 900 | 360 | 180 | Ø300 | 520 x 260 | Ø32 | 100 x 100 | 380 | 4 - Ø25 | 780 | 860 | 960 | 760 |

Bolster can be selected from standard round hole, square hole, pin-holes, or custom-made hole size.

| Model Number | CSP-25 | CSP-35 | CSP-45 | CSP-60 | CSP-80 | CSP-110 | CSP-160 | CSP-200 | CSP-260 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity tonf |

25 | 35 | 45 | 60 | 80 | 110 | 160 | 200 | 260 | |||||||||

| Stroke Length mm |

80 | 50 | 100 | 50 | 120 | 60 | 130 | 60 | 150 | 100 | 180 | 100 | 200 | 120 | 210 | 120 | 250 | 160 |

| Strokes Per Minute Constant Speed (standard) S.P.M. |

90 | 110 | 80 | 100 | 70 | 95 | 65 | 90 | 60 | 80 | 50 | 70 | 40 | 62 | 35 | 52 | 30 | 47 |

| Strokes Per Minute Variable Speed (special) S.P.M. |

70 | 110 |

80 | 140 |

60 | 100 |

70 | 130 |

50 | 85 |

60 | 120 |

40 | 75 |

55 | 110 |

40 | 75 |

50 | 100 |

35 | 65 |

45 | 90 |

30 | 50 |

35 | 70 |

25 | 45 |

30 | 60 |

22 | 40 |

30 | 50 |

| Tonnage Rating Point mm |

3.2 | 3.2 | 3.2 | 4 | 5 | 5 | 6 | 6 | 7 | |||||||||

| Shut Height (S.D.A.U.) mm |

240 | 200 | 250 | 220 | 270 | 240 | 300 | 280 | 330 | 300 | 340 | 330 | 400 | 360 | 450 | 400 | 470 | 420 |

| Slide Adjustment mm |

50 | 50 | 65 | 75 | 80 | 90 | 100 | 110 | 120 | |||||||||

| Slide Bottom Area mm |

350 x 260 | 400 x 300 | 460 x 350 | 490 x 400 | 580 x 460 | 660 x 520 | 720 x 580 | 860 x 660 | 960 x 760 | |||||||||

| Shank Hole Diameter mm |

Ø38.1 | Ø50.8 | Ø50.8 | Ø50.8 | Ø50.8 | Ø50.8 | Ø50.8 | Ø65 | Ø65 | |||||||||

| Bolster Area mm |

720 x 340 | 800 x 400 | 850 x 450 | 880 x 560 | 1060 x 620 | 1150 x 660 | 1350 x 760 | 1500 x 830 | 1600 x 900 | |||||||||

| Bolster Thickness mm |

85 | 90 | 95 | 105 | 135 | 145 | 155 | 180 | 190 | |||||||||

| Bolster Hole Diameter (standard) mm |

Ø120 | Ø120 | Ø130 | Ø150 | Ø160 | Ø200 | Ø300 | Ø300 | Ø300 | |||||||||

| Work Height mm |

755 | 780 | 780 | 810 | 820 | 860 | 860 | 900 | 920 | |||||||||

| Frame Inside Width mm |

400 | 480 | 524 | 540 | 600 | 680 | 750 | 900 | 980 | |||||||||

| Overall Size mm |

935 x 1120 | 1015 x 1210 | 1075 x 1320 | 1140 x 1435 | 1235 x 1650 | 1345 x 1820 | 1480 x 2090 | 1680 x 2270 | 1780 x 2450 | |||||||||

| Overall Height mm |

2015 | 2130 | 2320 | 2495 | 2760 | 2985 | 3295 | 3580 | 3800 | |||||||||

| Main Motor Constant Speed (standard) KW x P |

2.2 x 4 | 3.7 x 4 | 3.7 x 4 | 3.7 x 4 | 5.5 x 4 | 7.5 x 4 | 11 x 4 | 15 x 4 | 19 x 4 | |||||||||

| Main Motor Variable Speed (special) KW x P |

3.7 x 4 | 3.7 x 4 | 3.7 x 4 | 5.5 x 4 | 7.5 x 4 | 11 x 4 | 15 x 4 | 19 x 4 | 22 x 4 | |||||||||

| Slide Adjust Motor KW x P |

0.12 x 4 | 0.4 x 4 | 0.4 x 4 | 0.4 x 4 | 0.5 x 4 | 0.5 x 4 | 0.75 x 4 | 0.75 x 4 | 1.5 x 4 | |||||||||

| Air Pressure kgf/cm2 |

5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | |||||||||

| Die Cushion-to facilitate drawing (Optional accessory) |

||||||||||||||||||

| Cushion Capacity tonf |

2.2 | 2.2 | 2.2 | 6 | 6 | 8 | 12 | 13 | 14 | |||||||||

| Cushion Stroke Lenght mm |

60 | 60 | 70 | 70 | 85 | 95 | 110 | 120 | 130 | |||||||||

| Pad Dimensions mm |

280 x 200 | 310 x 210 | 340 x 220 | 400 x 250 | 440 x 320 | 480 x 330 | 540 x 420 | 550 x 400 | 720 x 540 | |||||||||

1.The above overall height excludes "rubber mount" height-(CSP-25:38mm, CSP-35~60:47mm, CSP-200~260:60mm )

2. Based on main factory production, rights of modification reserved.