5YRS

Dahching Electric Industrial Co., Ltd

Products

Grating Welding Machine

Grating Welding Machine

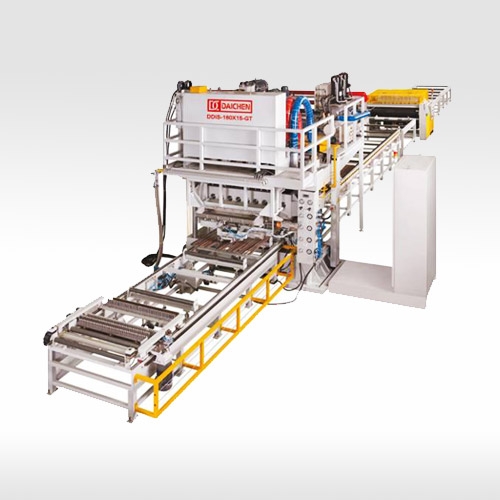

GT Model DDIS-GT

| Single / Dual Cross Bar Grating Welding |

| Energy Efficient Three Phase Inverter - DC Current Output Solution 70% energy savings can be achieved compared to a standard Single Phase AC machine Low connection load of 800kVA for dual bar welding with primary current being as low as 1400A Energy Efficient German Bosch Rexroth- DC Inverter- Power Supply German Bosch Rexroth DC Inverter power supply unit, provides efficient primary current control and constant current output ensuring reliable welds. High Return on Investment Low Energy Cost and Efficient Production Save up to 70% energy-savings or US$20,000 in costs per year thanks to low connection load requirements compared with other AC machines. High Production Efficiency Preloading System Without stopping the machine, operator loads the bearing bar onto the preloading system for auto feeding into the welding station thus enhancing safety and efficiency. Save Labor & Increase Safety Cross Bar Auto Loading System The pneumatic auto loader accurately feeds and positions two twisted bars into the correct welding position prior to welding. Stable & Excellent Welding Quality High current density, stable pressure from the heat treated cast iron head, and the support of four heavy duty steel columns results in high penetration and excellent welding quality. Cooling is Vital for Performance The Inverter DC transformers, electrodes and secondary coils are all water cooled. A chiller (Optional) is available for continuous diode cooling. A series of built in fans eliminate condensation and maintains system stability. |

Specification

| MODEL | DDIS-150X10-GT | DDIS-150X12-GT |

| Description | 150kVAX10 | 150kVAX12 |

| GRATING SPECIFICATION | ||

| Grating Size | 1000mm x 6000mm | |

| Bearing Bar | Thickness 6mm | Thickness 8mm |

| No. of Bearing Bars | 30 Pieces | 30 Pieces |

| Cross Bar Bar Square Twisted | 6 x 6mm | |

| Cycle Time | 9~10 Mins / Grating | |

| ELECTRICAL SUPPLY | ||

| Transformer Capacity Per Set | 150kVA | 150kVA |

| No. of Transformers | 10 Sets | 12 Sets |

| Input Voltage; Frequency | 380 / 415 / 440Vac, 50Hz | |

| Control Frequency | 1000Hz | |

| Max Short Circuit Current | 200,000A | 240,000A |

| Connected Load | 500kVA | 750kVA |

| Primary Power Connection Cable | 200mm2 Per Phase | 300mm2 Per Phase |

| Programmable Control and Interface | Japanese Mitsubishi PLC Controller with Japanese Proface 10” Human Interface System | |

| Servo Motor | Mitsubishi 7.0kW and 400W Servo Motor | |

| COOLING WATER AND PRESSURE SUPPLY | ||

| Cooling Water Supply | 150 L/Min | 150 L/Min |

| Chiller Capacity (Option) | 45 HP | |

| Welding Pressure | 70 Ton | |

| Hydraulic Pump | 210 KG | |

| MODEL | DDIS-180X12-GT | DDIS-180X15-GT |

| Description | 180kVAX12 | 180kVAX15 |

| GRATING SPECIFICATION | ||

| Grating Size | 1000mm x 6000mm | 1250mm x 6000mm |

| Bearing Bar | Thickness 8mm | Thickness 6mm |

| No. of Bearing Bars | 42 Pieces | 42 Pieces |

| Cross Bar Bar Square Twisted | 8 x 8mm | |

| Cycle Time | 9~10 Mins / Grating | |

| ELECTRICAL SUPPLY | ||

| Transformer Capacity Per Set | 180kVA | 180kVA |

| No. of Transformers | 12 sets | 15 sets |

| Input Voltage; Frequency | 380 / 415 / 440Vac, 50Hz | |

| Control Frequency | 1000Hz | |

| Max Short Circuit Current | 300,000A | 400,000A |

| Connected Load | 1,000kVA | 1,750kVA |

| Primary Power Connection Cable | 400mm2 Per Phase | 600mm2 Per Phase |

| Programmable Control and Interface | Japanese Mitsubishi PLC Controller with Japanese Proface 10” Human Interface System | |

| Servo Motor | Mitsubishi 7.0kW and 400W Servo Motor | |

| COOLING WATER AND PRESSURE SUPPLY | ||

| Cooling Water Supply | 200 L/Min | 280 L/Min |

| Chiller Capacity (Option) | 45 HP | |

| Welding Pressure | 70 Ton | |

| Hydraulic Pump | 210 KG | |