Products

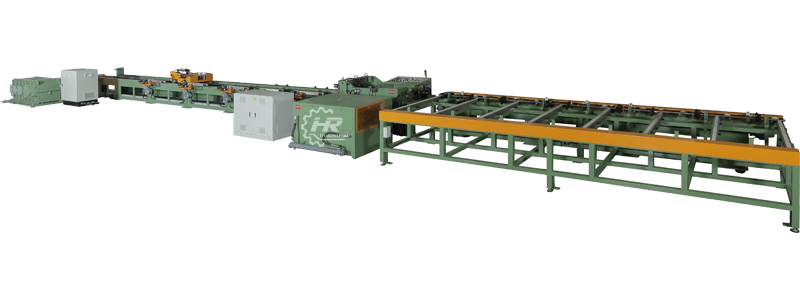

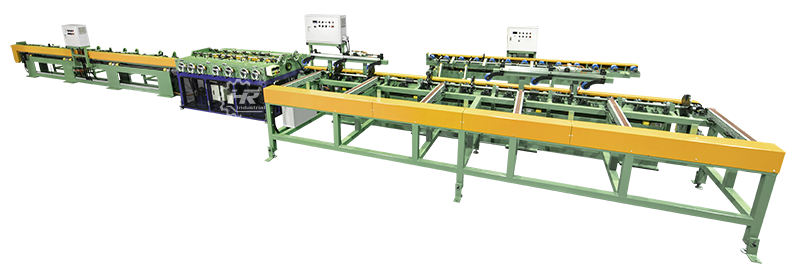

The Automatic Cold Drawing machine is chain-type machine which has equipped with loading machine, charging unit, hydraulic push pointer, and unloading arms. The HS model series is designed to streamline the cold drawing process by using a hydraulically powered extrusion unit (also known as push pointer) to clamp the stock piece and push it directly against drawing die. The drawn materials are then carried using unloading arms to designated collection racks next to the draw bench.

From loading to unloading, this entire process is controlled using a PLC control system, making it very efficient and ideal for automatic bar-to-bar drawing. The head-press mechanism replaces the swaging process that is normally required during traditional cold drawing. Moreover, the fully automated process reduces the need for costly manpower and helps streamline the precision drawing process. The automation from this HS model series is suitable for the drawing of round, hexagonal, and square metal bars.

※ Above specification, dimensions and designs are subject to change without prior notice.

What are the Benefits

. Processes Equilateral Workpieces with Hydraulic Push Pointer

. Fully Automated Loading & Unloading for Efficiency

. PLC Control System for Easy Operation

Specification & Capacity

Specification & Capacity