Products

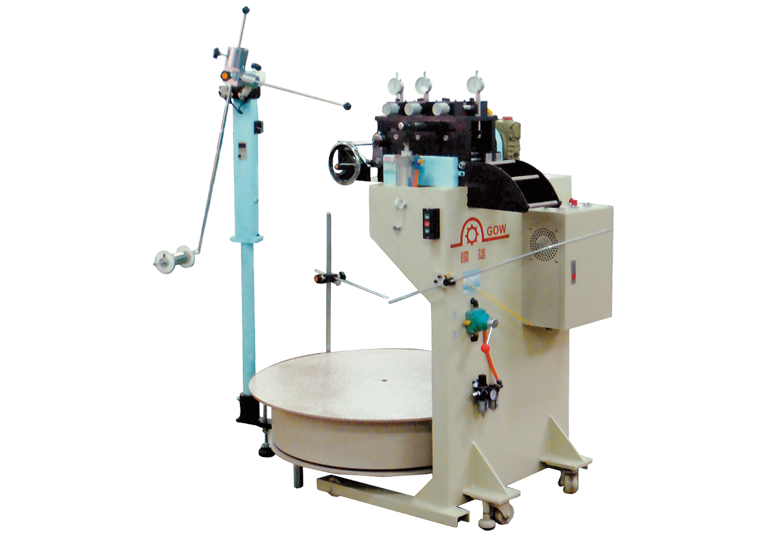

● The combination of CMT Type2(LEVELER) & CT1000 ● Type(HORIZENTAL TYPE DECOILER) is designed for saving the space.

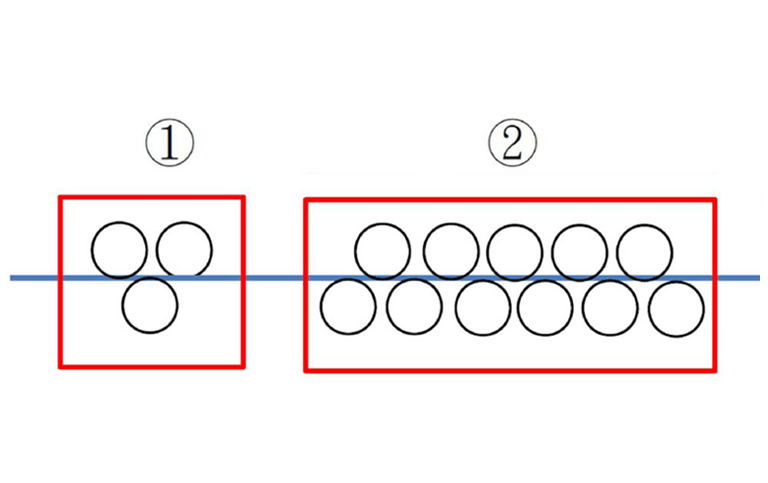

● The unique 2 section leveling designed for solving the high flatness and leveling stability of material requirement.

● Flip – Top leveler head device designed for easy maintenance operation.

● Adopting inverter driving motors to reduce thes cratching problem of the material surface.

● Manual type in feed coil guiding device to simplify the coil loading operation.

Accessories

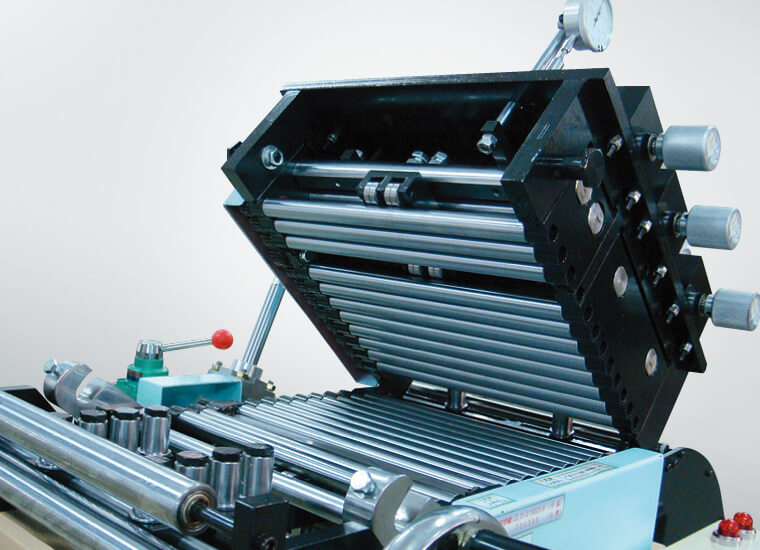

Flip – Top leveler head device.

The opening function is designed for cleaning the working rolls.

Specialty

- Height leveling

- Height stability

- Flip-top leveler head device

Leveler Rolls

CMT Series

| Modle | CMT-100 | CMT-150 | CMT-200 | CMT-300 | CMT-400 | CMT-500 |

| Width of Material (mm) | 100 | 150 | 200 | 300 | 400 | 500 |

| Thickness of Material (mm) | 0.1 ~ 0.6 | |||||

| Leveler Rolls (mm) | 20 x 22 pcs | 20 x 22 pcs | 20 x 22 pcs | 20 x 22 pcs | 20 x 22 pcs | 20 x 22 pcs |

| Leveler Motor (mm) | 1/2 | 1/2 | 1 | 1 | 1 | 2 |

| Leveler Inverter (mm) | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 |

Optional:

CT Series Electronically Controlled Horizontal Uncoiler

| Mode | CT-1000 | CT-1500 |

| Coil Weight (kg) | 1000 | 1500 |

| Max. Cool O.D. (mm) | 1000 | |

| Rotational Speed (R.P.M) | 0 ~ 24 | |

| Uncoiler Motor (HP) | 1/2 | 1 |

| Uncoiler Inverter (kW) | 0.75 | 0.75 |

All specifications, dimensions and design characteristics shown in this catalogue are subject to change without notice.

Standard Accessories

- Flip – Top leveler head device.

- Manual in feed coil guide device.

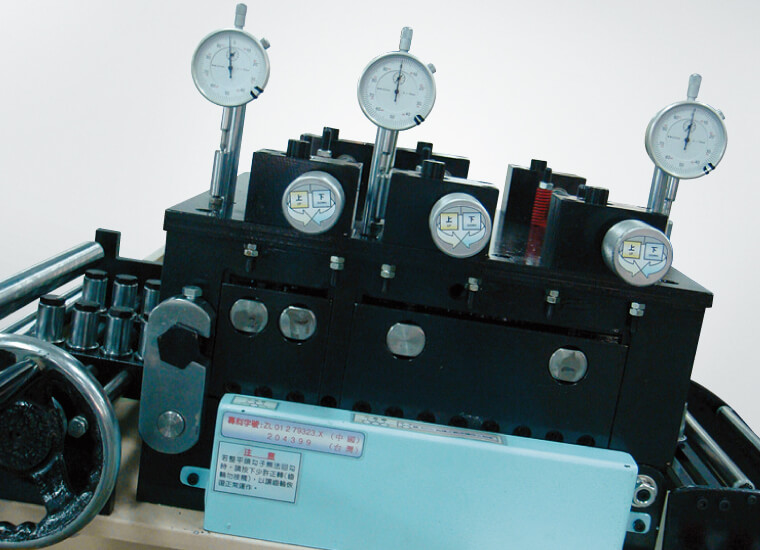

- 2 points micro adjustment with 3 sets. (Attached withdial gauge)

- Inverter.

- Touch loop control sensor.

Optional Accessories

- Ultrasonic speed loop control device.

- Photoelectric sensor.