Products

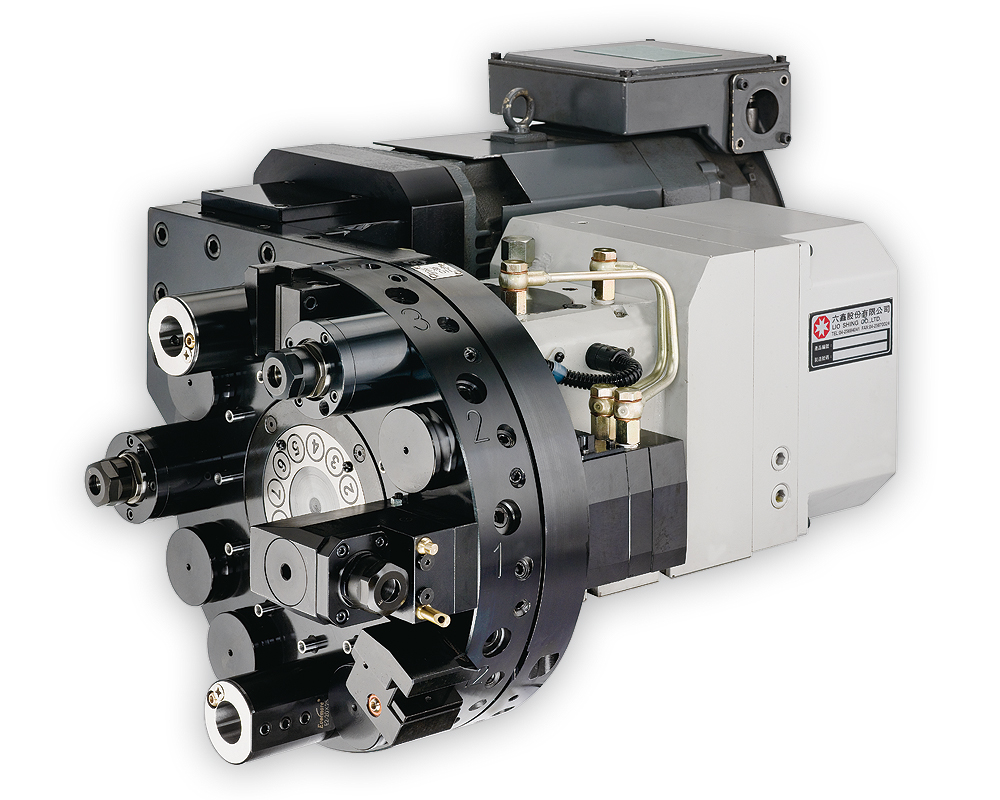

Powered Turret Features:

Turret rotation and indexing is driven by a special servo motor.

Tool holders are driven by a spindle motor that features high torque output and no noise.

Fast tool change without change error.

Powered tool holders meet DIN69880 and DIN5480 standards.

Repeatability accuracy reaches 0.003 mm.

Three-piece type curvic clutch ensures high positioning accuracy.

VDI Ø20, 12 tools, tools center Dia. Ø240 mm, Turret center height 63 mm

SERVO TURRET:

Mitsubishi Servomotor: HG-KR43JK ; Gear ratio 1/48

Hydraulic power source: P = 30 kg / cm²

Hydraulic cylinder clamping force 1,640 kg

POWERED TOOL HOLDER:

Tool shank specifications: DIN5480 W11 x 0.8 and zero detent system

Max. tool speed: 5,000 rpm.

Spindle motor specification:

Mitsubishi SJ-PF2.2-01 1.5 / 2.2 KW

Fanuc α1.5 1.1 / 2.2 KW

Tool and motor transmission gear ratio 1 : 1

Specifications And Accessories

| MODEL | LS-120SP | |

| Center height | mm | 63 |

| Number of tools | N | 8T / 12T |

| Rotating time (tool-to-tool) | sec | 0.42 / 0.4 |

| Rotating time (including locking) | sec | 0.52 / 0.5 |

| Total indexing time for 180° | sec | 0.83 |

| Total indexing time for 180° (including locking) | sec | 0.93 |

| Gear speed ratio | 48:1 | |

| Curvic couplings type | 3 Piece type | |

| Turret servo motor | HG-KR43JK MR-J4-40A-RJ |

|

| Hydraulic working pressure | Kgf/cm² | (25-30)30 |

| Flow rate | L/min. | 20 |

| Thrusting force of hyd. cyl. | Kgf | 1,640 |

| Accuracy of repeatability | mm | 0.003 |

| N.W (Without spindle motor) | Kg | 135 |

| Tool servo motor | MITSUBISHI - SJ-PF2.2-01 FANUC - α1.5 |