Products

Best value and most versatile machine available for all production shops.

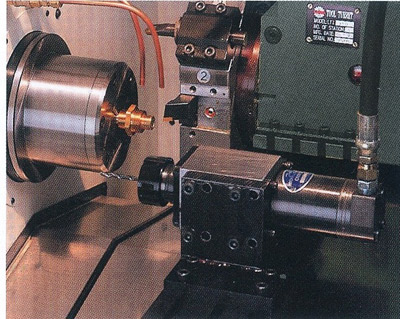

Optional hydraulic live tools, Both facing and crossing, Allows secondary combined with 48-position spindle indexing or C-axis. Good for various secondary operation.

Can be used as a gang tool machine or an optional 8-position turret.

Use of an optional bar feeder for unattended high volume production.

Live tool

Hydraulic live tool with the spindle 48 dividing system and C-axis function can make secondary operation on the machine.

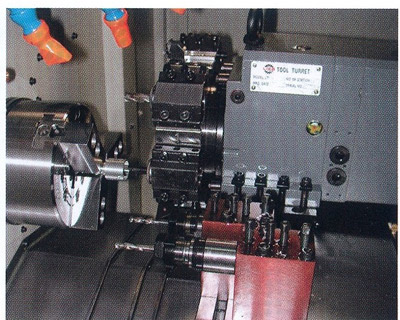

High speed, high precision indexing turret

The 8-position tool turret ensures high repeated positioning accuracy and rigidity. Rapid indexing time from 0.15 sec. to 1.2 sec, The tool disc has a built-in coolant nozzle that is directed straight to the tool tips.

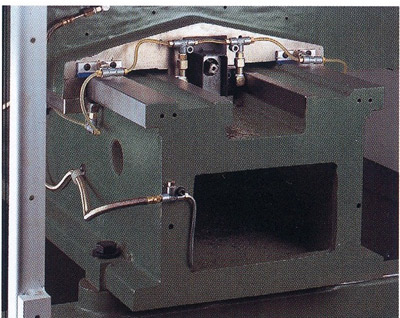

Live tool

Insures high rigidity. TURCITE coating allows for smooth and precise movements. Telescopic cover protect the ballscrew.

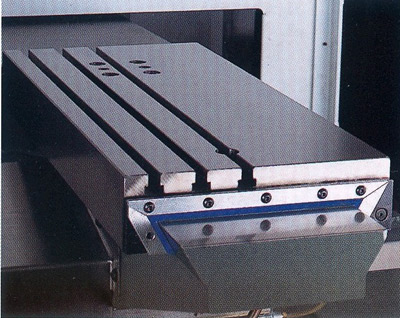

The dovetail X-axis slide

permits mounting of gang tools (sub plate also available) and or hydraulic tooling spindle as well as an 8-position turret with thru coolant.

Standard controller

Either "MITSUBISHI" M64SL or "SIEMENS" 802D or FANUC OiMATE controller.

3-Jaw hydraulic chuck

This machine can be equipped with a Ø06" or Ø 8" 3-jaw hydraulic hollow chuck as option. For enlarge workpiece machine.

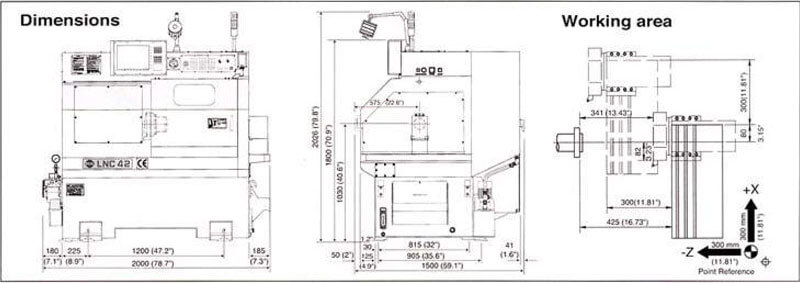

| Content | Unit | LNC42 | LNC65 | |

| Capacities | ||||

| Collet bar capacity , dia. (through bore) | mm | Ø42 | Ø65 | |

| Max. swing | mm | Ø260(Ø10.2”) | ||

| Max. turning diameter(3-jaw power chuck) | mm | Ø165(Ø6.5”) | Ø195(Ø7.7”) | |

| Max. turning length | collet | mm | 300(11.8”) | |

| 3-jaw power chuck | mm | 270(10.8”) | 254(10”) | |

| Spindle | ||||

| Height of spindle center (approx.) | mm | 1000 | ||

| Spindle nose | - | ISO A2-5 | ISO A2-6 | |

| Collet chuck type | - | F48 | F72 | |

| Power chuck reception | inch | 6 | 8 | |

| Spindle drive | ||||

| AC motor cont. output | kW | 5.5(7.5HP) | 7.5(10HP) | |

| Maximum torque | Nm | 42 | 95 | |

| Max. spindle speed | rpm | 5000 | 4000 | |

| Slide | ||||

| Cross travel (X-axis) | mm | 300 | ||

| Longitudinal travel (Z-axis) | mm | 300 | ||

| Resolution | mm | 0.001 | ||

| Tool turret | ||||

| Number of tool positions | - | 8 | 12 | |

| Turning tool section | mm | □20 (□3/4”) | ||

| Boring tool reception | mm | Ø25 (Ø1”) | ||

| Servo motors | ||||

| Working feeds ,X-axis and Z-axis , stepless | mm/min | 0~6000 | 0~10000 | |

| Rapid traverses ,X-axis and Z-axis, stepless | m/min | 10/15(option) | 10/15(option) | |

| Feed force 100% duty factor , X-axis | kg/cm | 24.4(0.5 kW) | 32.6(0.83 kW) | |

| Feed force 100% duty factor , Z-axis | kg/cm | 48.7(1.0 kW) | 56.1(1.4 kW) | |

| Space requirements and weights | ||||

| Overall dimension (L x W x H) | mm | 1870 x 1440 x 1650 | ||

| Approx. net weights of machine with electronic cabinet | kg | 1800 | 2000 | |

| Hydraulic tank capacity | liters | 40 | ||

| Hydraulic pump motor | kW | 0.75 | ||

| Coolant tank capacity | liters | 150 | ||

| Coolant pump motor | kW | 0.25 | ||

| Lubrication capacity | - | 2 L,6c.c./12min | ||

| Total power required | KVA | 24 | 28 | |

- Collet chuck LNC42 F48 (Max.Ø42)

- Collet chuck LNC65 F72 (Max.Ø65)

- Hydraulic system

- Coolant system

- Automatic lubrication system

- Work lamp

- Front door safety interlock

- Tool box & tool kits

- Control cabinet heat exchanger

- Spindle dividing system (48 pos.)

- Bar feeder interface

- Foot pedal for collet & chuck open/close

- Standard tool holders

- 6” hollow power chuck (LNC42)

- 8” hollow power chuck (LNC65)

- Chip conveyor with cart

- Parts catcher

- Extra tool holder

- Automatic bar feeder

- Tool turret 8 pos. for LNC42

- Tool turret 12 pos. for LNC65

- Rotary tool with hydraulic system