Products

Based on the principle of not changing the cutting fluid concentration and base oil, the main leakage (oil slick) is effectively removed, anaerobic bacteria formation and acidification of the cutting fluid are prevented.

It improved the water tanks of the die-casting plant and screwing machine, electroplating plant, cleaning machine, milling machine ,CNC lathes, drilling machines, grinders, cutting machines and other machine which be corroded and leaking, and it can also improve the odor problem, the instability of PH, and the cost derived from the Labor、Maintenance.

The Oil skimmer of Green Eco Pro would maintain the original concentration of the cutting fluid and it is differentthe with general Oil skimmer,as steel belt type, disc type, chain type oil skimmer on the priciple to remove the oil. The waste oil collected after separation has a high concentration and can be recycled at a price.

‧ Built-in oil storage barrel, patented STPM module, patented floating skimmer

‧ No consumables, small size, continuous circulation

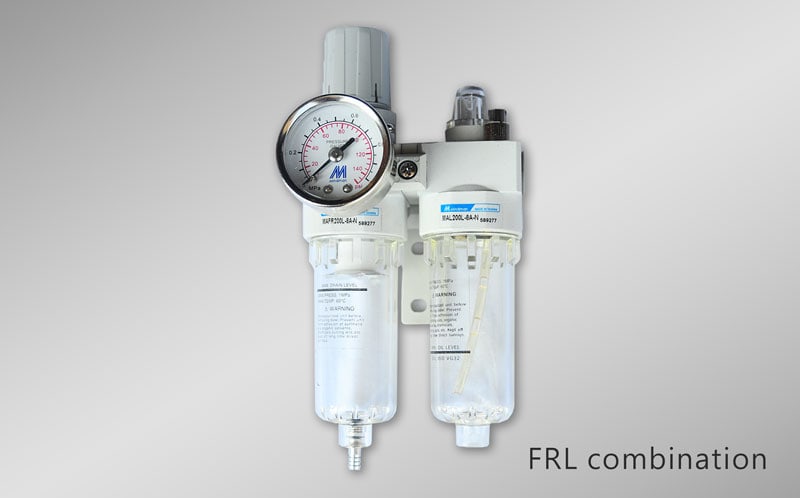

‧ Pneumatic pump, safe and no leakage concerns

‧ Purify and process waste water-based cutting fluid to improve annoying odor

‧ Consumables for removing waste oil and making oil mist recovery machine for using longer

‧ Extend tool life, reduce tool wear and replacement costs of machine tools

Features

Reduce cost of coolant

- Lower 50% of the cost, Extend life time for quintuple

Recycle waste oil

- Filter the waste oil and saving cost 15%

Automatic processing

- Operator’s health is priceless and cost down 15% manual work

Pure Oil Recycle

- Increase Pure Oil Recycle 10%, promote high value

Specification

| Item | Ultra360 |

|---|---|

| Size | 500*218*715 (L*W*H/mm) |

| Max Flow | 360 L / Hr |

| Volume | 14 L |

| Net Weight | 28 kg |

| Oil Volume | 2 L |

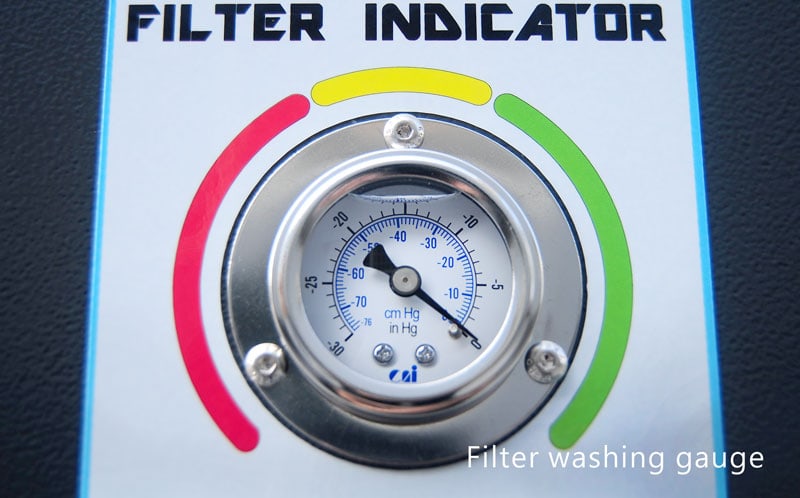

| Filter Obstruct Meter | Standard |

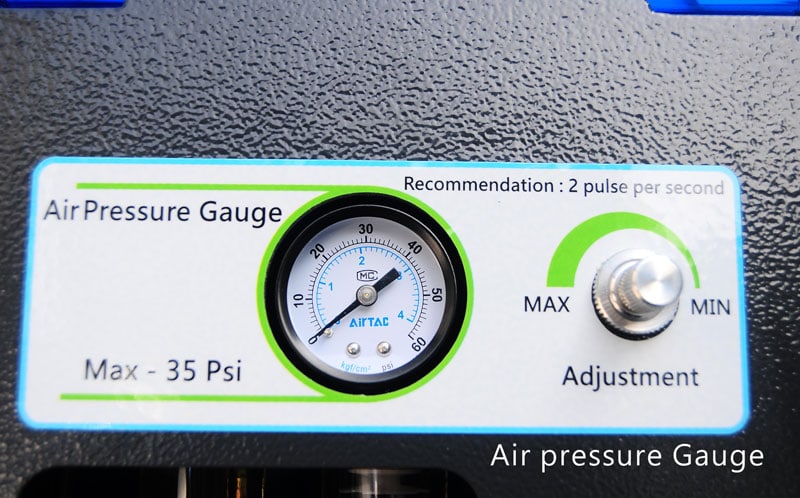

| Power | Air Pump Minimum Start Pressure 2.5 kg/ 35psi |