Products

With a view to meet the ever increasing market demands, present day plastic processors have resorted to the use of plastic raw materials which included all kinds of sophisticated ingredient such as glass fiber additive, carbon fiber, mineral stone powder additive, heat-resisting chemical additive, etc., thereby causing serious abrasion and to the barrel and screw as well as reducing their life span. To meet this challenge, our Co. had several kinds of screw which has shown a remarkable anti-abrasion and anti-corrosion resistance in its practical application. Not only PTA treatment on screw flights, also developed the technique of hardness coating of the entire screw surface, so as to bring more benefits to the processors.

Fully-Hard

| Model | Process | Hardness | Application Glass Fiber | Recycle Material | Wear Resistant | Corrosion Resistant |

|---|---|---|---|---|---|---|

| S-23 | Vacuum + Plasma nitriding |

HRc > 60 | >30% | >50% | ★★★★☆ | ★★★★☆ |

| S-04 | Vacuum + Plasma nitriding |

HRc 58-60 | 15%-30% | 30%-50% | ★★★★ | ★★★★☆ |

| S-79 | Vacuum + Plasma nitriding |

HRc 58-60 | 15%-30% | 30%-50% | ★★★★ | ★★★ |

| S-88 | Vacuum + Plasma nitriding |

HRc 48-50 | <15% | <30% | ★★ | ★★★★ |

Powder Steel: The mechanical specifications of powder steel are better than tool steel. The heat treatment stability is also better than tool steel; furthermore, it is easier to estimate the deformation after heat treatment. Due to the better hardness, toughness and it can temper in the high temperature, so powder material is suitable for PVD coating.

Tool Steel: Because of include high percentage of C and Cr, tool steel has good anti-abrasion performance and also good toughness performance. Mo and V provide the tool steel has high impact and good heat treatment stability.

Stainless Steel: High percentage of Cr provides stainless steel has outstanding anti- corrosive. The hardness can achieve to over HV 1000 after plasma nitride. .

Fully-Coat

| Model | Process | Hardness | Application Glass Fiber | Recycle Material | Wear Resistant | Corrosion Resistant |

|---|---|---|---|---|---|---|

| S-42 | Powder coating | HV1100-1400 | 30%-50% | >50% | ★★★★★ | ★★★★☆ |

| S-75 | Powder coating | HV900-1100 | >30% | 30%-50% | ★★★★☆ | ★★★★★ |

Fully Coat screw is use HP/HVOF (High pressure/ High velocity Oxygen Fuel) technology to coat the alloy powder on the entire screw surface.

It means alloy powder spraying is under high pressure and high velocity (3-4 times sonic). The adhesive force is over 10000PSI, and the powder density can achieve to 99.8%.

PTA-Weld

| Model | Process | Hardness | Application Glass Fiber | Recycle Material | Wear Resistant | Corrosion Resistant |

|---|---|---|---|---|---|---|

| S-59 | PTA welding | HRc 52-55 | <15% | <30% | ★★★ | ★★★ |

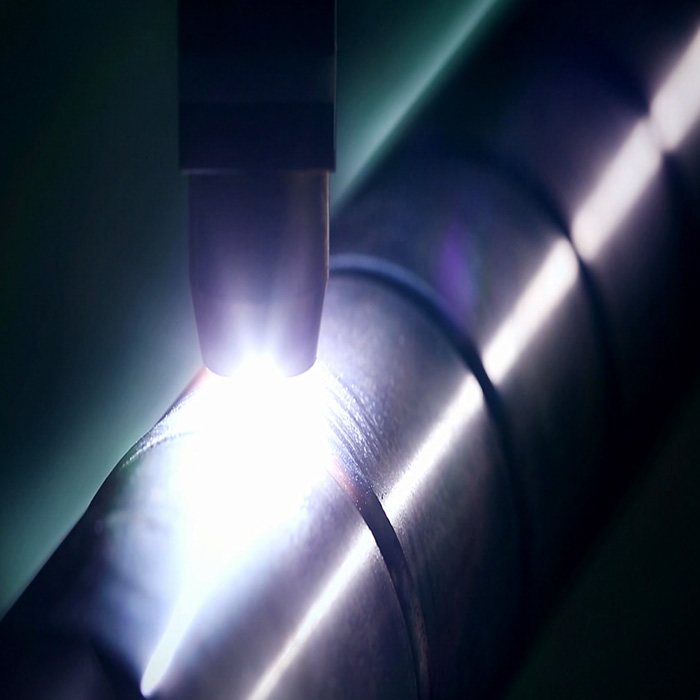

Plasma is a gas which is heated to an extremely high temperature and ionized so that it becomes electrically conductive.

The plasma transfer arc welding process uses this plasma to transfer an electric arc to the screw flight. The metal to be welded is melted by the intense heat of the arc and fuses together.