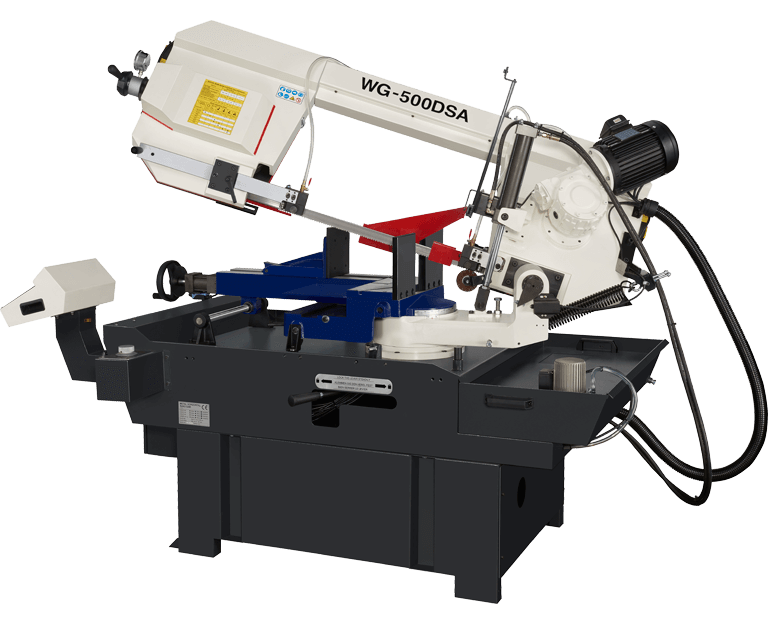

Products

H350 W500

Double miter cutting (R60˚ / L45˚) by manual.

The new design of telescopic control box can avoid the interference while the sliding vise base movement,and reduced volumetric efficiency.

Human-Machine-Interface control panel provides easy and simple operating system for users,and build-in 6 error conditions with display on screen (DSAH).

The separation of down feed knob from control panel is easier to operate.

The linear bearing is used in the sliding vise base for move smoothly and operational method.

Sliding vise base can avoid the interference during the angle cutting.

Rack type quick action vise and hydraulic vise clamping.

Motor inverter controlled blade speed to provide a high efficiency and variable speed conversion.

Mobile coolant tray is convenient for catchment during the angle cutting.

Material feeler is used to detect cutting height automatically to reduce cutting cycle time.

It's available in a choice of panels.

Specifications

| Capacity 90° | ● 350 mm ▅ 330 mm ▅▅ 200 x 500 mm |

Capacity 45° | ● 330 mm ▅ 250 mm ▅▅ 145 x 340 mm |

| Capacity 60° | ● 210 mm ▅ 135 mm ▅▅ 125 x 220 mm |

Capacity 45°(L) | ● 290 mm ▅ 230 mm ▅▅ 60 x 345 mm |

| Blade Size | 34 x 1.1 x 3880 mm | Blade Speed | 20 ~ 85 mpm |

| Blade Motor | 3 HP (2.2 kw) | Hydraulic Motor | 1 HP (0.75kw) |

| Coolant Motor | 50 W | Container Loads | 6 units / 20', 12 units / 40' |

| Packing Size | 2240 x 930 x 1770 mm | N.W./G.W. | 677 kg / 757 kg |