Products

Work-piece (Wire frame) Feeding

Loaded in 1~2 piece of the wire frame in the Jig Guide and push it towards the central of welding machine by means of track.

Cross Wire Feeding

Double automatic cross wire loading carriage with double wire hopper, one is at front side ; another at back side for sorting, positioning and ejecting straightened, cut to length cross wires at the same time. Either can work at the same time for duel face mesh or can work only one side for single face mesh.

Pull out Device

By means of servo motor control and gripping pliers, wire frame being pulled up step by step based on the pre-set pitch after welding with cross wires until one cycle finished. Then, servo motor returns to initial point. Unloaded finished mesh manually. No tolerance accumulated problem.

Welding machine

According to the wire welding pitch, the machine can adjust cylinders, electrodes, and gripping pliers. Adjustable of each point welding time and welding current for the most proper electrode stroke and perfect use of electrode dies. Certain amount of electrodes mounted on front and back sides for welding wires on both face at the same time.

Controlling System

By means of P.L.C along with touch-off screen, all the parameters of system, and figures could be set on the screen. And also with the function of trouble shooting warning. Easy for operating and maintenance.

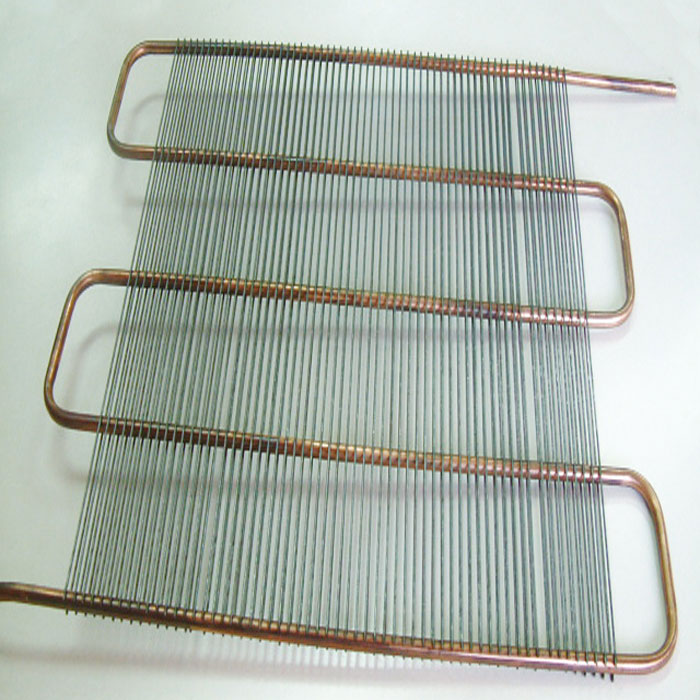

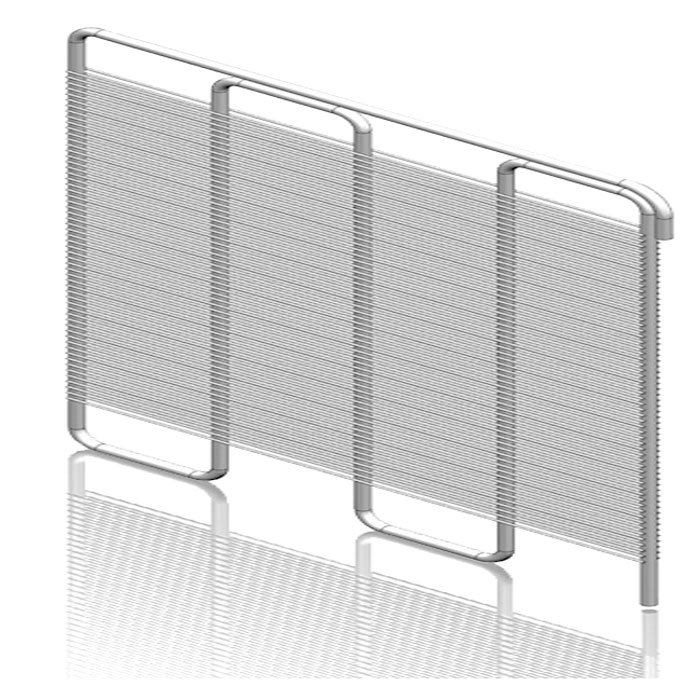

Applications

Wire Shelves in refrigerator ,Radiator mesh ,evaporator Radiator mesh ,Wire shelving, wire mesh, evaporator shelves.

Feature:

1.Cross wires auto feeding with the high production rate.(0.6sec/line)

2.Quick change-over, easy and quick to re-set different sizes of wire mesh.

3.Future looking versatility by modular system to incorporate options to meet for future requirement.

Specification Table:

| Model | Frame Height mm |

Cross Wire Length |

Wire mm |

Tube Diameter mm |

Mesh Eyes mm |

|---|---|---|---|---|---|

| GSV-80B/1200 | 300~700 | 300~1200 | 1.4~1.6 | Ø5~Ø8 | ≧50*9 |

Related Products