Products

CFB Ceramic Fiber Brush

● Ideal for removing cutter marks, surface polishing and deburring.

● CFB is hard bristle, suitable for processing surfaces and simple - shaped workpieces.

● Patented Design: The brush projection length is adjustable with interval of 10mm for truing worn brush or application of stepped workpiece.

● The brush can be replaced when it is totally worn out.

● Performance: There are 6 types of brush granularity and each CFB ● Ceramic Fiber Brush can be assembled according to customer demands of granularity.

Application:

● The hard bristle is made of mixing high strength ceramic fibers and resin, ideal for processing flat surfaces or simple-shaped workpieces.

● Applicable for all steels, aluminum, copper, nickel alloy steels with hardness less than HRC52.

● High temperature with standability: 400°C.

● Workable for both dry and wet machining, but flood coolant is recommended because coolant through center will affect processing.

DDB DIAMOND DRESSING BOARD

● The front surface is coated with high hardness of diamond powders for truing the worn bristle. The brush can be used continuously.

Ideal for use with CFB CERAMIC FIBER BRUSH and DMB DIAMOND BRUSH.

● The plate is light-weighted aluminum alloy, easy operation.

● Wet machining is recommended to let coolant fluid flush away the dust and particles, maintaining a healthy working environment.

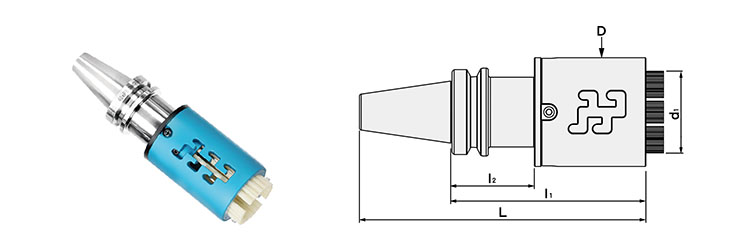

DualDRIVE+ SBT/CFB CERAMIC FIBER

| MODEL NO. | TYPE | L | l1 | l2 | D | d1 | ADJUSTABLE BRUSH LENGTH |

BRUSH TYPE | WEIGHT (KGS) |

|---|---|---|---|---|---|---|---|---|---|

| 25.802.040.125 | SBT30xCFB40-125 | 173.4 | 125 | 45 | 55 | 36.5 | 12.7 ~ 40 | DB-50 | 1.20 |

| 25.802.050.125 | SBT30xCFB50-125 | 173.4 | 125 | 45 | 65 | 46 | 12.7 ~ 40 | DB-50 | 1.23 |

| 25.802.063.125 | SBT30xCFB63-125 | 173.4 | 125 | 45 | 78 | 59 | 12.7 ~ 40 | DB-50 | 1.66 |

| 26.802.040.120 | SBT40xCFB40-120 | 185.4 | 120 | 40 | 55 | 36.5 | 12.7 ~ 40 | DB-50 | 1.65 |

| 26.802.050.120 | SBT40xCFB50-120 | 185.4 | 120 | 40 | 65 | 46 | 12.7 ~ 40 | DB-50 | 1.69 |

| 26.802.063.120 | SBT40xCFB63-120 | 185.4 | 120 | 40 | 78 | 59 | 12.7 ~ 40 | DB-50 | 2.11 |

| 26.802.063.165 | SBT40xCFB63-165 | 230.4 | 165 | 60 | 78 | 59 | 15 ~ 65 | DB-75 | 2.55 |

| 26.802.080.120 | SBT40xCFB80-120 | 185.4 | 120 | 40 | 95 | 76 | 12.7 ~ 40 | DB-50 | 2.43 |

| 26.802.080.165 | SBT40xCFB80-165 | 230.4 | 165 | 60 | 95 | 76 | 15 ~ 65 | DB-75 | 2.90 |

| 26.802.100.120 | SBT40xCFB100-120 | 185.4 | 120 | 40 | 115 | 96 | 12.7 ~ 40 | DB-50 | 2.81 |

| 26.802.100.165 | SBT40xCFB100-165 | 230.4 | 165 | 60 | 115 | 96 | 15 ~ 65 | DB-75 | 3.34 |

| 27.802.040.125 | SBT50xCFB40-125 | 226.8 | 125 | 45 | 55 | 36.5 | 12.7 ~ 40 | DB-50 | 4.33 |

| 27.802.050.125 | SBT50xCFB50-125 | 226.8 | 125 | 45 | 65 | 46 | 12.7 ~ 40 | DB-50 | 4.36 |

| 27.802.063.125 | SBT50xCFB63-125 | 226.8 | 125 | 45 | 78 | 59 | 12.7 ~ 40 | DB-50 | 4.79 |

| 27.802.063.150 | SBT50xCFB63-150 | 251.8 | 150 | 45 | 78 | 59 | 15 ~ 65 | DB-75 | 4.98 |

| 27.802.080.125 | SBT50xCFB80-125 | 226.8 | 125 | 45 | 95 | 76 | 12.7 ~ 40 | DB-50 | 5.11 |

| 27.802.080.150 | SBT50xCFB80-150 | 251.8 | 150 | 45 | 95 | 76 | 15 ~ 65 | DB-75 | 5.34 |

| 27.802.100.125 | SBT50xCFB100-125 | 226.8 | 125 | 45 | 115 | 96 | 12.7 ~ 40 | DB-50 | 5.49 |

| 27.802.100.150 | SBT50xCFB100-150 | 251.8 | 150 | 45 | 115 | 96 | 15 ~ 65 | DB-75 | 5.78 |