Products

Machine feature

1. Rigid U, V truss design

2. Stainless steel worktable with hardness HRC 50°.

3. Machine Casting is designed based on the FEA analysis for increasing the rigidity.

4. Machine base with extra wide.

5. Water Cooled lower arm prevents thermal expansion caused by heat buildup. Therefore, the accuracy will be improved.

To ensure thremal balance, RIB location is designed by finite element analysis (FEA)assuring and optimized rigid structure.

Specification

V1060 - Z350 / Z500

Max. work piece size: 1500 x 1000 x 345 mm (495 mm)

Wire diameter: 0.2 - 0.33 mm

Max. work piece weight: 3000 kg

Number of axes controlled: 5 Axis AC servo motor

Table travel of X Y: 1000 x 600 mm

Maximum taper angle: ±30°/ 100mm with wide diamond guide and nozzle

U & V axis travel: 160 x 160 mm(260 x 260 mm)

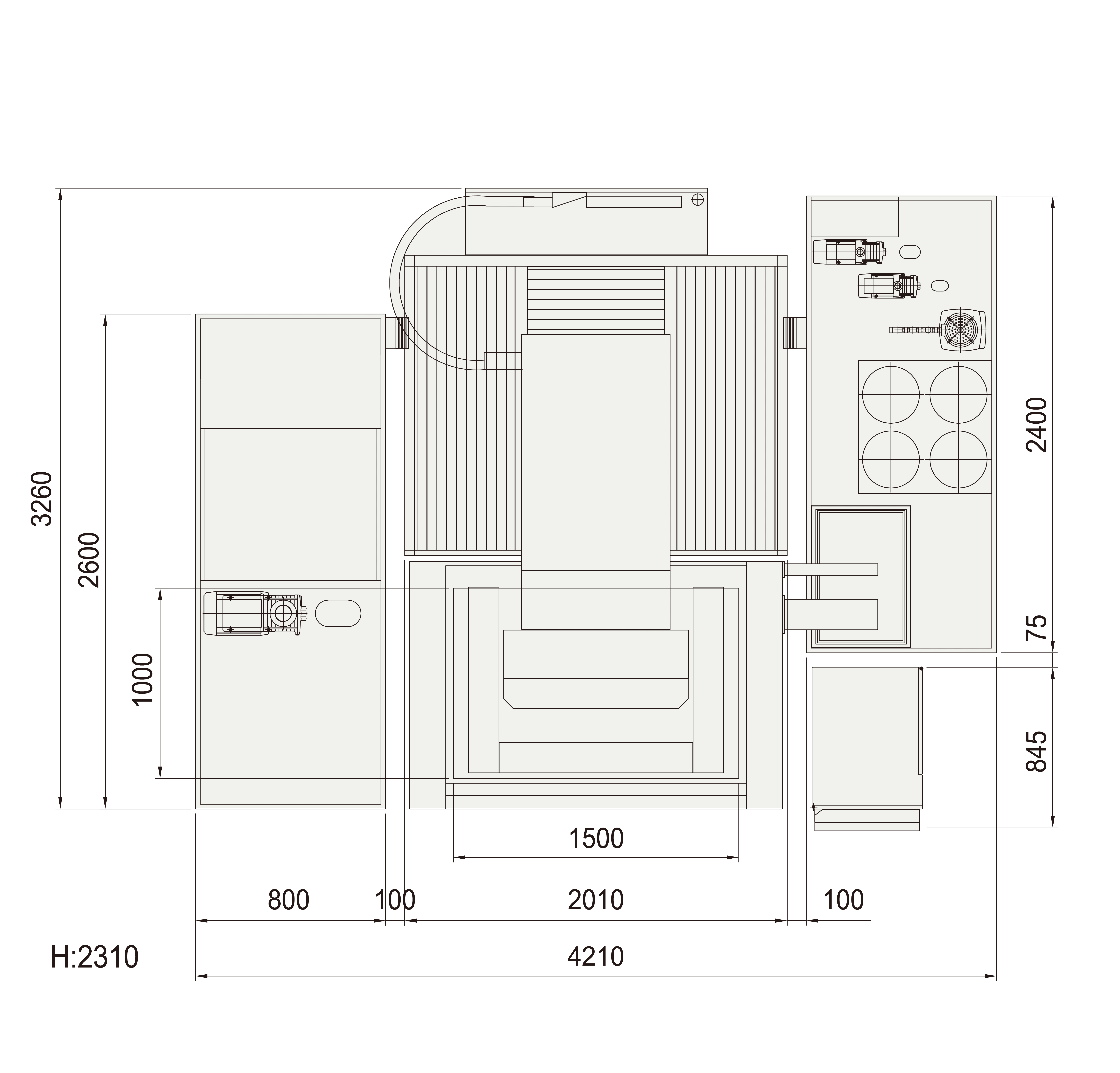

Machine size: 3460 x 3260 x 2310 mm (Z350)

4210 x 3260 x 2390 mm (Z500)

Z axis travel: 350 x 500 mm

Machine weight: V1060 - Z350 / Z500 : 7300 / 7650 kg

Water tank capacity: V1060 - Z350 / Z500 :

1800 / 2500 L

* Travel of Z axis (Option): 500 mm(Submerged height 500 mm)

Standard Accessories

- Ion exchange resin x 10L

- Paper filter x 2 pcs

- Diamond guide x 2 pcs

- Upper and lower flushing nozzle x 2 sets

- Energizing plates x 2 pcs

- Brass Wire x 1 spool

- Clamping tool x 1 set

- Vertical alignment jig x 1 set

Options

- XY axis linear scale

- W-Axis

- Clamping Beam

- Jumbo Feeder L-50A

- AWT

- Double Door

- AVR 15KVA

- Transformer 15KVA

- Short Message Service (SMS)

- Signal Tower

- Remote Monitor System

- Super Finish Circuit