| 1. |

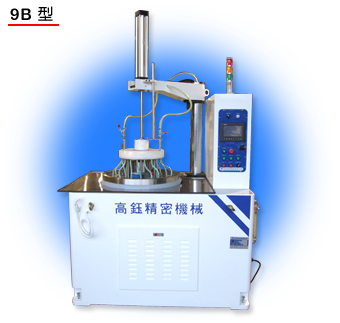

The machine is suitable for mass production and high precision operation. |

| 2. |

Flatness precision for work piece can reach 0.2μ -0.5μ. |

| 3. |

The machine is applicable to work on things with different shapes and different at the same time. |

| 4. |

There is no influence on temperature and distortion, even if the work piece is as thin as 0.20m/m. |

| 5. |

Maintenance of the grinding disk is available during manufacturing process, which there is no need to stop. |

| 6. |

Uses a 4-way planetary operation. |

| 7. |

The upper and lower grinding disk, and the center gear wheel are independent and driven directly. |

| 8. |

The upper grinding disk can sway to 90 degrees, functions with back pressure during descent, and possess a five-stage pressurization function. |

| 9. |

Operation uses Japan-made OMRON which has program control and touch screen (or products with the same grade). |

| 10. |

Thickness control uses Japan-made Mitutoyo optical ruler control, which has the function of setting 5 sets of parameters (or products of the same grade). |

| 11. |

The pressure of air uses FESTO digital valves from Germany, which precision is to two places behind decimal point (or products of the same grade). |

| 12. |

According to the client’s requirements, can designate the brand of components for use or change the machine design. |