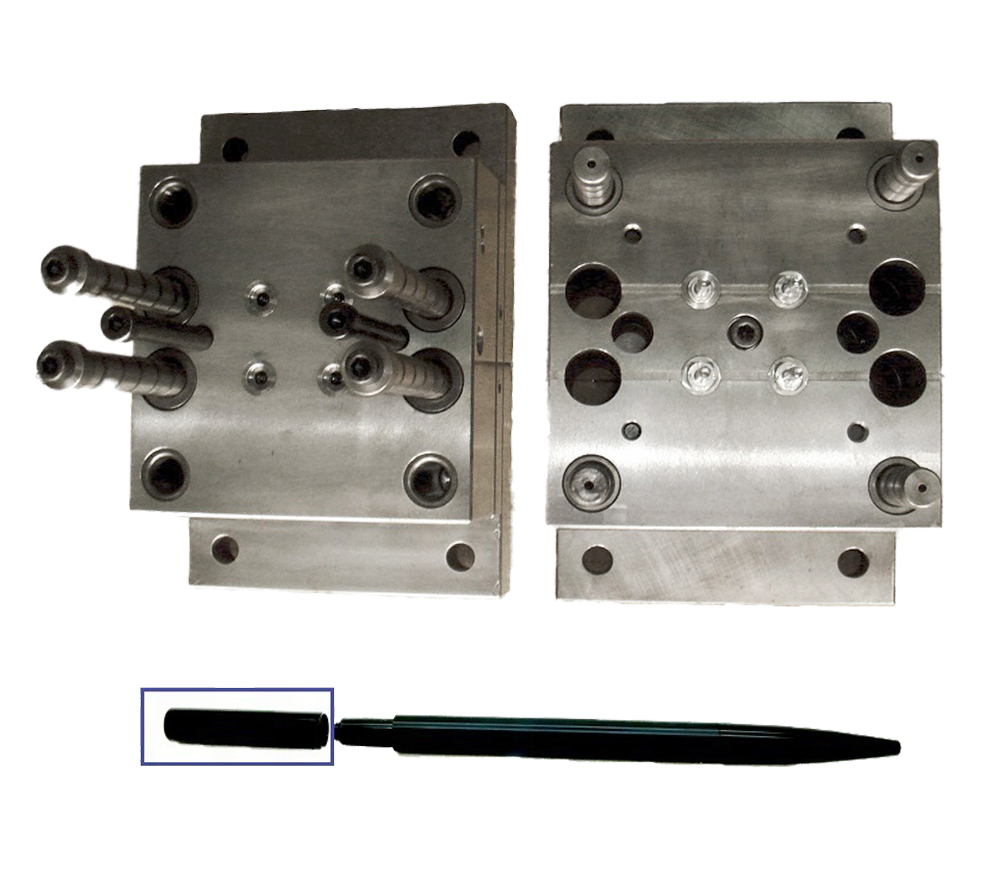

Products

The molds for such components are typically relatively small, so they require high-precision design, processing, and manufacturing to ensure that each produced part meets the specifications. They often have complex shapes and details, such as the curves of the pen body, the shape of the pen tip, and the cap of the pen cap. The molds must accurately reproduce these details to ensure the appearance and functionality of the final product.

Product Features

Molds for manufacturing eyebrow pencil components need to have high precision, the ability to reproduce complex shapes, high wear resistance, and an optimized cooling system to ensure high-quality and efficient production of the product. This requires the careful design and manufacturing of custom molds to meet the unique requirements of eyebrow pencil components.

| Material | stainless steel, carbon steel |

| Color | nickel white |

| Mould Base | LKM |

| Mould Base Material | S50C |

| Core Material | M310 |

| Cavity QTY | 4 cavities |

| Runner | cold runner |

| Gate | Pin gate |

| Mould lifetime | 300,000~500,000 shots |

| Design software | UG, CAD |

| Mold flow software | Moldex 3D |

| Plastic part material | PP |

| Mould dimension | Length : 200 Width : 300 Height : 250 mm |

| OEM and ODM | Acceptable |

| Packing | Wooden package or as your request |