SANE KUEI MACHINERY CO., LTD.

Products

Silicon Powder & Fluid Switchable EDM

CNC Series : Silicon Powder EDM

P60 / P90

Using both powder and dishcarge fluid for CNC mirror surface finishing.

The X, Y& Z axis utilizes AC servo motor.

Multi cavities machinng, ORBIT-CUT machining & Helix machining.

A.T.C. (Automatic Tool change) & C-axis machining available.

The Circle Angle of Sparking is lower than 0.02mm.

The best surface roughness (Ra) is better than 0.1 µm.

High speed and long distance jumping

Multi-side ORBIT-CUT machining for X, Y & Z axis

Widespread application on plastic mold, rubber mold, die-casting mold, 3C products

Power machining enables high stability & efficiency 30% more than general electric discharge machining.

The work tanks of discharge fluid and powder are separated individually.

Specification

|

Specification

|

P 60

|

P 90

|

| X, Y-Travel |

400 x 300 mm

|

500 x 400 mm

|

| Z-Travel |

300 mm

|

300 (290) mm

|

| Table Dimension |

600 x 320 mm

|

760 x 440 mm

|

| Work Tank Dimension |

800 x 540 x 280 mm

|

1050 x 660 x 360 mm

|

| Max. Table-Quill Distance |

500 mm

|

680 mm

|

| Max. Electrode Weight |

50 kgs

|

100 kgs

|

| Max. Table Loading |

800 kgs

|

1200 kgs

|

| Dielectric Tank Capacity |

200 + 200 Litre

|

400 Litre

|

| Filters |

2 PCS

|

3 PCS

|

| Machine Weight |

2100 kgs

|

2550 + 520 kgs

|

| Machine Height |

2240 mm

|

2450 ~ 2600 mm

|

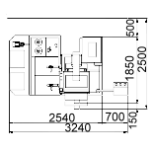

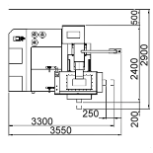

| Ground Area |  |

|

| Nominal Current | 30A / 5A, 45A / 5A, 60A / 5A |

| Input Voltage | 220 / 380 / 415 / 440V |

| Connected Rating | 4KVA / 5.5KVA / 7KVA |

| Max. Stock Removal Rate | 200 / 300 / 400 mm³ / min |

| Best Surface Roughness | Ra ≦0.1μm |

| Best Electrode Wear Rate | < 0.2% ( specific equip.< 0.1%) |

|

Standard accessories

|

Additional Equipment

|

| Precision Electrode Clamps | ATC (Auto Tool Change) |

| Piezoelectric Light | C-Axis |

| Magnetic Induction Oil Nozzle Base | "EROWA" Chuck-Swiss |

| Operation Manuals | 3R System Chuck-Sweden |

| M.F.D (Fine mirror Finish) | Automatic Fire Extinguisher |

| Di-electric Cooler | |

| Permanent Magnetic Chuck | |

| Silicon Powder x 2 kg | |

| X, Y, Z Axis Linear Scales (1μm) |