Products

Features

A. Stable construction, strong rigidity, low vibration, and high cutting accuracy.

B. Suitable for wider material or multiple pieces cutting at one time.

C. Fixtures with two way force from top and two sides. That makes clamp irregular objects easily, don't need to use special fixtures, shorten working time, and increase the productivity.

D. Auto powerful oil mist coolant ensures clean machined surface and endure tool life.

E. Servo feeding, cutting size is within the tolerance of +/-0.1mm.

F. Touch screen control system is easy to operate.

G. High power design ensures fast sawing and high productivity.

H. By using electrical saw blade protection device, saw blade will stop working automatically when the saw blade is dull to ensure safety and clean machined surface.

I. Install powerful chip collector, collect chip automatically and clean easily.

J. After cutting finish, retreat knife behind the bilateral material returned, saw without tooling trace, cutter surface smooth.

K. Saw blade can all use from 305-610mm, avoid to waste material.

L. NC control, can to cut more kind of size and quantity.

Standard Accessories

a. Basic machine

b. Auto oil mist spraying system

c. Tool box

d. Electronic saw blade protection device.

e. NC control system

f. Tungsten steel saw blade(455mm*1 pc)

Optional Accessories

a. chip collector

b. Roller type material shelf

c. Inverter

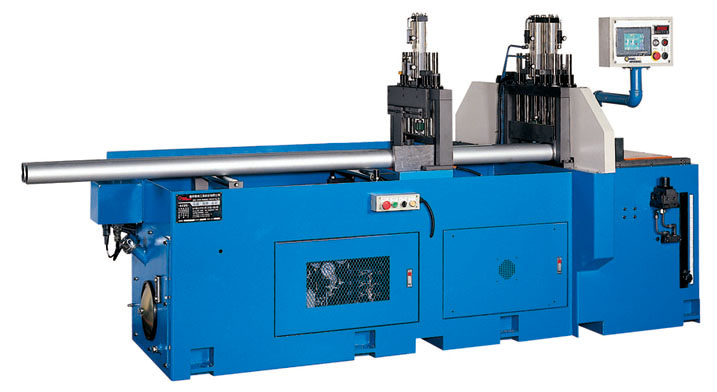

| Model | NC-610-3ASE |

| Cutting Capacity | 210/420 mm |

| Automatic Feed Stroke | 700mm per time, reciprocating feed stroke up to 9900mm |

| Feed Position Accuracy | +/-0.01 mm |

| Saw arbor Speed | 1200-3600 rpm |

| Saw arbor Motor | 15 HP |

| Servo Motor | 2 KW |

| Saw Blade Size | 610(24")x25.4mm |

| Used Circular Saw Blade | 305-610mm |

| Working Air Pressure | 6 kg/cm2 |

| Machine Dimension (mm) | L2950xW2150xH1600 mm |

| Machine Weight(kg) | 1600 kgs |