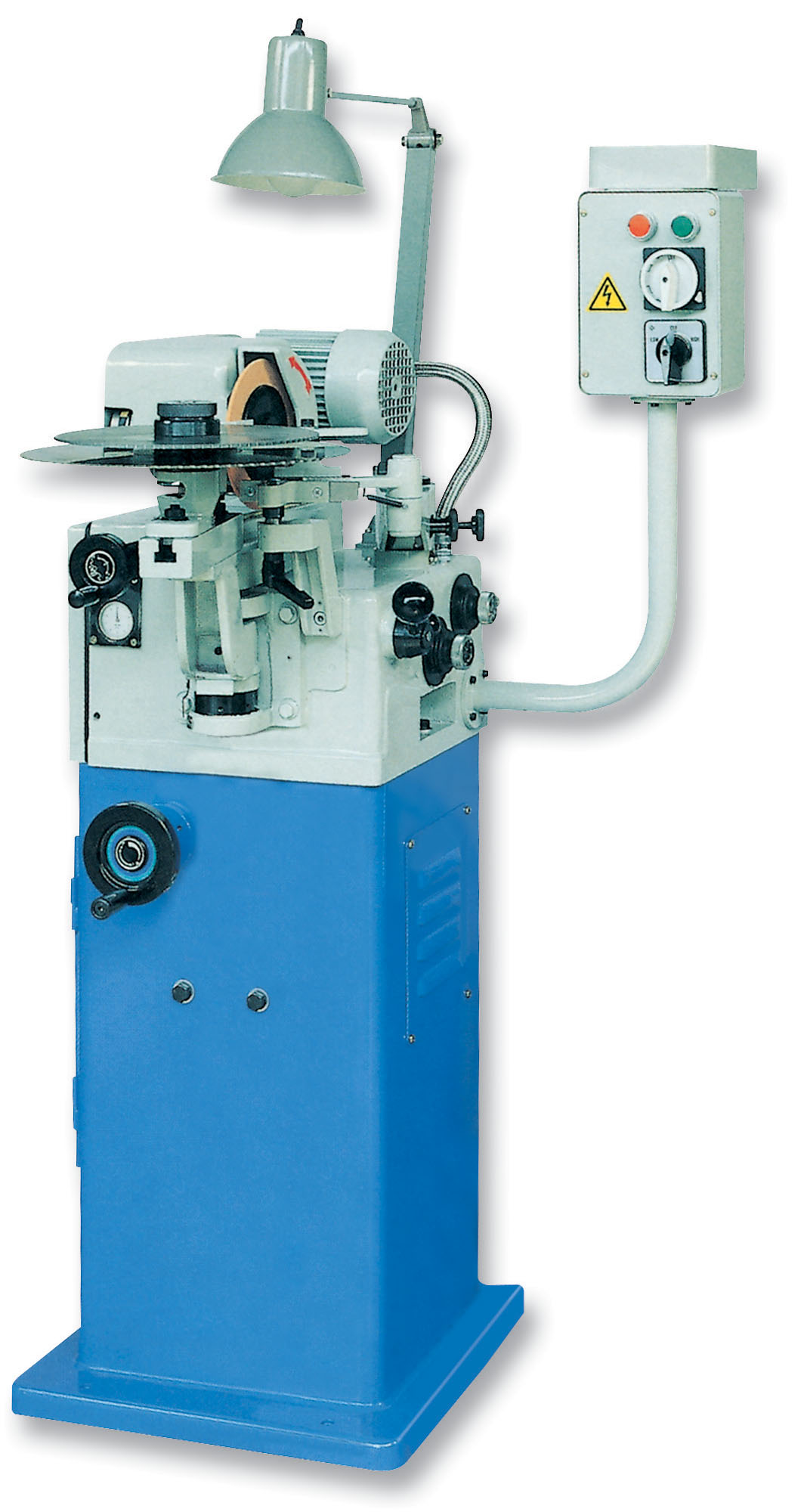

Products

Features:

A. All cast-iron components are made from DUCTILE IRON(FCD-45), wear resisting to assure precision.

B. Simply shift between Straight tooth(A type) and Curved tooth(B type). During saw blade install, the blade thickness setting is quick and accurate according an indicating meter.

C. Driving speed change by a stepless adjusting device, regard to change speed for different blade pitch promptly.

D. Alternate high/low teeth shall be accomplished by one pass. The teeth height difference is variable and read out from indicating meter, thus you got a prefect sharpening result.

E. Teeth chamfering is easily made without need to replace grinding wheel, only swings upward or downward to aim the indication plate.

Standard Accessories

a. Grinding wheel*10 pcs

b. Index plate*2 pcs

c. Working lamp*1 pc

d. Tools*1 set

Optional Accessories

a. Grinding wheel

b. Index plate

c. Dust suction equipment

d. Small saw blade holder(available min.50mm)

e. Enlarged saddle & holder(available max. 650mm)

| Model | C-450-2 |

| Saw blade dia. | 50-450mm |

| Pitch range | max. 25mm |

| Depth of teeth | max. 8mm |

| Range of cutting angle |

-5 degree~30 degree |

| Feeding speed | 45~180 teeth/min |

| Thickness of sawblade | max. 8mm |

| Grinding wheel dia. | 75~150mm |

| Wheel inner dia. | 25mm |

| Grinding wheel speed | 4200 rpm |

| Grinding wheel motor | 0.55 kw 2P |

| Driving motor | 0.37KW 2P/4P |

| Dust suction motor | 0.37 KW 2P(optional accessories) |

| N.W./G.W. | 150/180 KGS |